From Pits to Pots: Indigo Dyeing Traditions of the Maranse of Burkina Faso

Technology’s Stories v. 7, no. 2 – DOI: DOI: 10.15763/jou.ts.2019.06.13.01

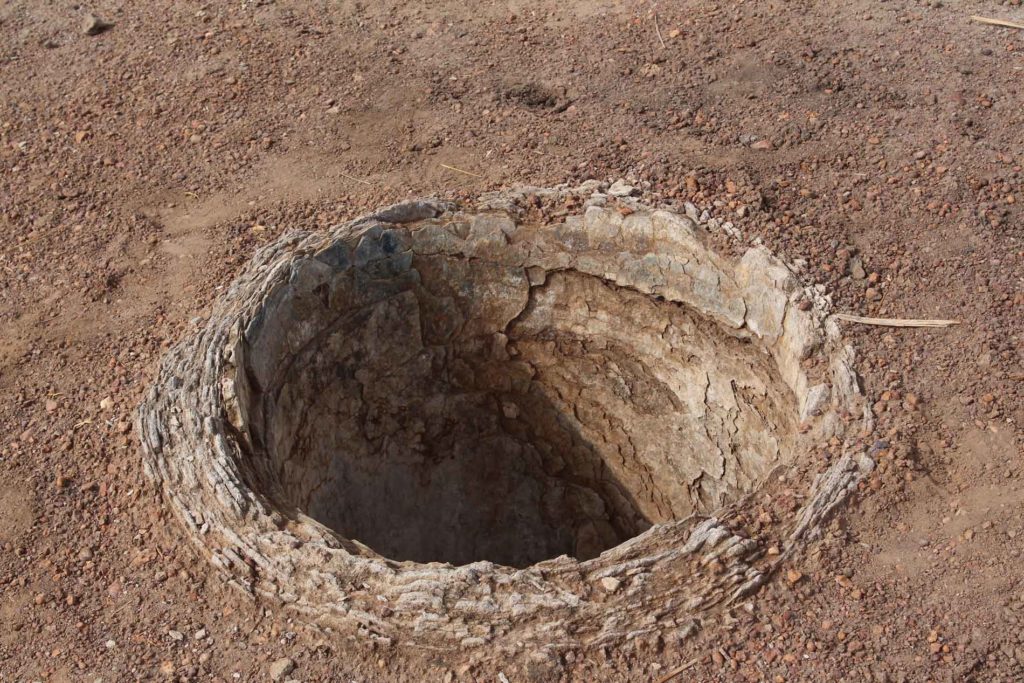

The abandoned sites of dyeing pits in the village of Zomkalga in northern-central Burkina Faso show the long-standing economic significance of an indigo industry that was developed by the Maranse in the first half of the 18th century[1] and that flourished from the second half of the 18th century in the Yatenga.[2] The pits, below-ground structures that hold the light-sensitive indigo dye vat or bath, appear in the landscape as large vases buried to the neck in the clay soil.[3] The capabilities of the Maranse dyers of Zomkalga is evident in the 602 pits built over more than two centuries. Most of the pits are today broken (Figure 1), filled in with earth or hidden under the foundation of new houses. The use of pots for indigo dyeing—above-ground and within individual households—has replaced the below-ground, community-held pit techniques.

The progressive abandonment of dye pits as the preferred technology among the Marense in the mid-1960’s. Thirty-eight years later, the shift to above-ground pot-dyeing, and the accompanying substitution of synthetic indigo for the natural colorant, was complete. The change required a collection of material and technological choices accepted, if gradually, by the entire community. The choices reflected environmental constraints and were motivated by economic interests; they were also affected by frictions that built over time within the dyers’ pit site that had progressively integrated non-Maranse newcomers since the early 20th century. This article looks at the social contexts surrounding the shift from a traditional set of practices using natural indigo in an open and communal site to the use of imported dyestuffs and a system of clay jars by individuals within their homestead. My comparison of the two techniques of dyeing will focus on social changes in the Maranse’s community of practice that also led to the redefinition of Maranse’s technical system.[4]

The dyeing pits of the Maranse

Pits for dyeing textiles indigo are found across West Africa, including in the Dafina and Samogo regions of Burkina Faso, in the Kolokani region of Mali, in Northern Benin and in Central and Northern Ivory Coast.[5] The “Maranse” so-called by the Mossi, migrated to the Yatenga region in stages from the early 17th century, not long after the fall of the Songhai empire. By the 18th century, Maranse Muslim traders known as the Kirakoya (“kings of salt”) had established indigo cultivation and dyeing in Zomkalga, two very lucrative activities previously unknown to the villagers or to the Mossi of the Yatenga at large.[6] The Kirakoya set up their quarters on the periphery of Zomkalga at this time, too, establishing a large site for indigo pits they called Marangho.[7] (Figure 2)

Indigo dyeing in pits: technology and materials.

Indigo dyeing in Zomkalga has since its origins in the 18th century been an activity of Maranse men. Each dyer (siino lobko) built his own pit (siino gano) beyond his living quarters (panto) on a communal site.[8] This location, far from the busy areas of the village, limited accidental damage to the vats from animals or curious children, and to some extent spared people the strong odor of fermented indigo dye, reminiscent of rotten eggs especially when the indigo bath lacked potash.[9] The pits were dug and rendered during the dry season, and if possible built on a mound.[10]

The dimension of the pit was a technical choice of the builder, who adapted its size and shape not only vis-à-vis the existing pits but also to make himself more comfortable. The adaptability of the pit can be seen at the dyeing site located in the Samogo village of Kougny (northern Burkina Faso) in 2014 (Figure 3). In Zomkalga, an average pit was two meters deep and 90 cm in a diameter, with a rim about 37 cm height that served as seat. Pits were built about 90 cm apart as measured on the site.

To pit-dye textile fabrics, such as women’s wrappers (Figure 4) and men’s traditional sleeveless gown and trousers, the dyer filled the container with about 400 liters of water. To this, he added six large loaves (about 3 kilograms each) of indigo, plus twenty kilograms of wood ashes to fix the dye on the fiber. Preferred sources for the ashes were the shea tree (Vitellaria paradoxa) or the marula tree (Sclerocarya birrea). Finally, zarta, a white powder based on the ashes of indigo residues from the vat is used as a supplemental mordant. Its addition revitalizes the dye so it can quickly fix onto the fabric; zarta also reduces the excess of potash from tree ashes. A carefully-tended indigo vat, one completely filled with dye to prevent the pit wall from breaking, could last years or decades. The indigo plant, known locally as gara zaaté (Indigofera arrecta, Fabaceae family) (Figure 5) was cultivated by women in ¼ hectare fields around the village.[11] They collected leaves and made them into balls or loaves that they would also sell on the market.[12]

Pits sites as an indigo dyeing community of practice

A mêrêgo (an “assembly” or a “gathering”) of indigo dyers worked at a communal pits site dyeing cotton cloth and yarns brought to them by their customers.[13]As many as five wrappers could be dyed in one day.[14]

On the site, they shared their knowledge, techniques and experience about indigo dyeing with their apprentices and later with the Mossi and Foulsé who in the early 20th century joined their site.[15] The pits site allowed this community of practice to share stories, gossip, tips and the workload.[16] It also accommodated meaningful or personal conversations among the dyers who could thus benefit from others’ support and motivation.[17] The pits sites and the dyer communities of Zomkalga followed a protocol of social rules called haigarou that was mediated by the oldest dyers or chief of the community and that today remains a cultural heritage. This protocol forms the basis of Maranse society and is extant as knowledge, practice, usages, customs and prohibitions observed to maintain the cohesion of the Maranse community at large. The social and ritual dimensions of the Maranse’s haigarou contributed to the shaping of the pits site dynamics and are to some extent materialized in its structure.

First, the concentration of pits at one communal site, which increased whenever a dyer joined the community, encouraged sociability. Indigo dyers became through their practical interactions a strong network of assistance; this in turn constituted part of the group identity. Mutual engagement meant dyers were not only bound to each other through practice ruled by their haigarou: they were also symbolically ‘fixed’ to the site. The first pit, built and used by the ancestor who founded the site, was protected by a magical stone placed under its foundation.[18] Its purpose was to protect the site, its material content and the dyers from enemies and evil entities that would corrupt their work by damaging their health or spoiling the dye. This magic created a sense of ontological security that would bind the dyers in a safe and thus productive place. For these foreign dyers (the Maranse), the foundational pit also was a form of physical appropriation and attachment to their new land. It provided a means to “dwell” in the place through building and expanding the site over time.

Furthermore, each dyer was bound to the pit of his father, the place where he learned to dye cloth with indigo. The genealogies of the dyers are materialized in the pits’ layout, as fathers, sons and brothers located their pits in adjacent areas. Social and family relationships were maintained through the dynamics of the exchange of ideas, of conflict resolution and of mutual assistance which are the principles of the haigarou. Respect for those dynamics at the workspace, as well as its physical configuration, ensured efficiency and so the productivity of the working group.

Second, the cohesion of the dyers’ community was maintained through yearly ritual actions performed by the chief of the Maranse and his assistants on the pits site. From the foundation of the site until the late 1980’s, a black ox was bought by the dyers and sacrificed at the bottom of the site every three years. Its dark color was reminiscent of the ultimate color achieved on cotton cloth with indigo. Each dyer would drop a symbolic drop of the animal’s blood in his pit to protect the dye from impurities such as oil or substances made by witches that would spoil the bath. A spoiled vat forced the dyer to empty, clean and purify his pit, and to remake the dye vat. This delayed work considerably since a new bath needed between one and three weeks to properly ferment. The sacrificial act was a psychological reinforcement, asking God to raise up dyers’ prayers to remain in good health and to bring luck, and many clients, to their business (the large numbers of dyers meant competition was tight). The triennial ox was replaced later by a black sheep that was sacrificed yearly. As the use of synthetic indigo that began in Zomkalga in the mid-1960s grew, dyers left the site to dye in their own compound. The sheep that was sacrificed was later replaced by a black rooster as the community of dyers shrank until the pits site was completely closed in 1998.[19] This story highlights the ritual downturn through the choice of smaller animals as the group of dyers shrank and also illustrates the social weakening and the fragmentation of the dyers’ community of practice.

From natural dyes in pits to synthetic dyes in pots

The technical transition from pits to pots was instrumental in bringing social change to the Maranse’s community of dyers. The gradual decision, made individually by each dyer, to replace natural indigo cultivated on their land—part of the French Sudan—between 1880 and 1960, with synthetic materials produced by Badische Anilin and Soda Fabrik (BASF), the German company that first commercialized synthetic indigo in 1897, had longstanding repercussions. In a report published by the Gouvernement général de l’Afrique occidentale française in 1904, the French engineer-agronomist Jean-François Vuillet had noted that “natural indigo keeps on fighting honorably against synthetic products produced from Baden and Frankfurt and against the other chemical blue colorings.”[20] In Zomkalga, natural indigo progressively lost ground to the synthetic dye (Figure 6) so that by the mid-1960’s even once-skeptical dyers were convinced to adopt it. The synthetic indigo proliferated in local markets. It became an economic ideal to dye in pots, as pit dyeing required vast amounts of synthetic materials to fill in the vat the dye.[21] This shift to synthetic indigo sparked the decisions to replace the pits that were no longer economically viable with large clay pots produced by local potters.

An additional technological shift occurred with efforts to substitute metallic drums for both pits and pots: it was believed that they would last longer and permit the dyeing of larger quantities of fabric; they also proved ergonomically more suitable. However, the corrosion of the metal was said to affect the quality of dyestuff.[22]

Across the Yatenga, Maranse dyers faced drastic environmental challenges as water shortages meant that the 400 liters of water required for each pit could no longer be spared.[23] As local trees (which were used to produce the natural potash required in the indigo vat) decreased in number it became forbidden to cut them down.[24] Another significant factor in the decision to abandon pits dyeing was the increasingly multi-ethnic nature of the community of practice. Maranse dyers welcomed Mossi and Foulsé apprentices but the haigarou, especially its ritual practices, could not entirely be shared with the non-Maranse and its principles were not always observed by non-Maranse who were native populations. Hence, tensions that built across time among the dyers affected the cohesion of the group. As a result, after the mid-1960’s, dyers began to work alone at their homestead as clay pots and synthetic indigo allowed to leave the pits site to practice their craft.

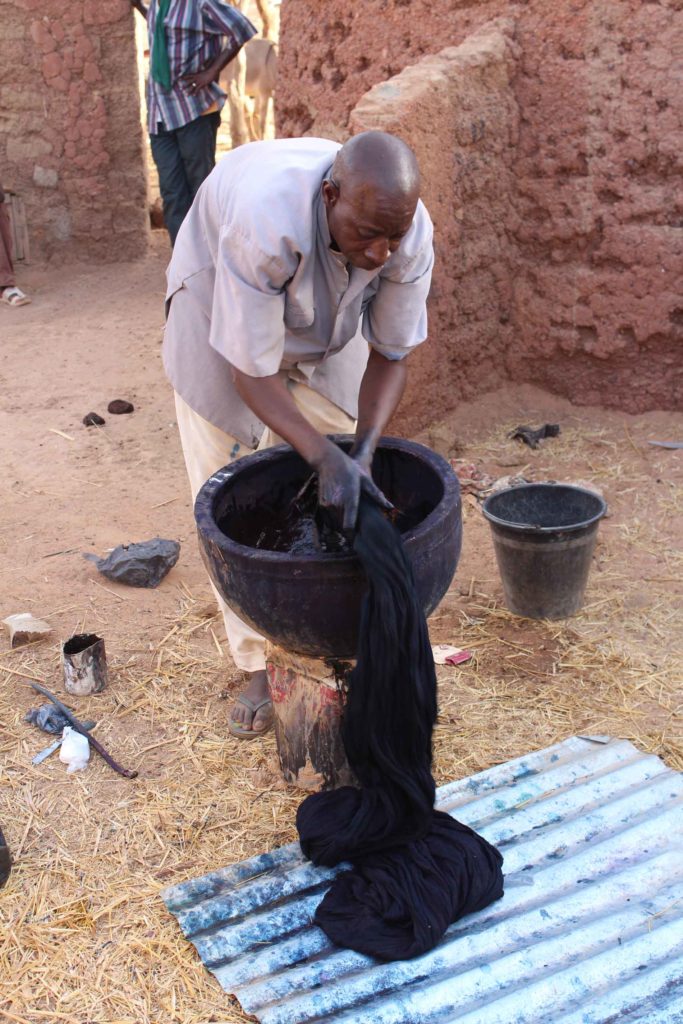

The Maranse dyer Noufou Kirakoya began to dye at his homestead in 1977: he remains active today. As shown in Figure 7, he uses two 10-liter jars set on the ground or on an elevation in a dedicated corner of the family compound. One jar is used for soaking fabrics in water containing potash to purify the fabric and the other one for dyeing. Although the chemical substances used to dye affect the health of the dyers, dyeing in pots facilitates the dyeing of locally-woven fabrics by reducing the cost and time of production. About 50 wrappers can be dyed in a day when using synthetic dyestuffs, as opposed to the 4 or 5 wrappers that were typical when pit-dyeing with natural indigo. The material and technological choices of indigo dyers offered multiple benefits: the dye could be prepared in smaller containers, the processes required less water and no ashes, and production increased.

The dyers’ economic interests, added to the rarity of the resources needed to continue the natural dyeing system, led to the break-up of the community as dyers progressively withdrew from the site. Dyeing in pots led to individualism and dyers no longer meet and chat with each other or with the villagers who would stop by the site or spend the afternoon there.[25]

Conclusion: socio-technical changes and spatial transition

The technical and material transition from dyeing cloth with local and natural materials in pits to dyeing with synthetic European-made dyestuff that occurred from the mid-1960’s strongly impacted the cohesion of the Maranse’s dyers community of practice. Maranse dyers had shared a history and repertoire of knowledge and techniques that was ruled by their ancestors’ haigarou and that provided cohesion to the society as it enabled its continuity and control. A complex set of social relations were embedded in the specific practices of a pit technology that allowed sociality and networks of support to develop amongst the dyers since looking after the site but also after each other was a collective responsibility. However, environmental constraints such as scarcity of water and of trees for ashes used to make the dye, the greater economic advantages of synthetic materials and frictions between Maranse and non- Maranse dyers led the dyers to choose to dye in pots in their home. The change provided privacy, but it also caused the dissolution of the community of dyers, of the sociability and bring about a change in social values.

Laurence Douny is a visiting research fellow at the Max Planck Institute for the History of Science, in Berlin. She is conducting research on the history and anthropology of West African wild silks and indigo dyeing industries in Burkina Faso, Mali and Ivory Coast.

Bibliography and Notes

Afrique occidentale française. Gouvernement général de l’Afrique occidentale française. Territoires du Haut-Sénégal Moyen-Niger. 1900-1903. Paris: Impr. de Firmin-Didot, 1904.

Gardi, Berhard. Gardi, Bernhard. Woven Beauty: The Art of West African Textiles. Basel: Museum der Kulturen : Christoph Merian Verlag, 2009.

Gosselain, Olivier P, and Lucie Smolderen. “Les fantômes du Dendi Lorsque surgissent les restes d’une ancienne filière textile au Nord Bénin.” Techniques & Culture 65–66, no. 1 (2016): 452.

Héritier, Françoise, and Michel Izard. Les Mossi du Yatenga: étude de la vie économique et sociale, par Françoise Izard-Héritier et Michel Izard, … Antony: Les auteurs, 4, rue de la Prairie], 1959.

Holas, Bohumil. “Teinturiers Mossi à Dimbokro.” Notes africaines., no. 38 (1948): 18–21.

Izard, Michel. “La politique extérieure d’un royaume africain : le Yatênga au XIXe siècle.” Cahiers d’études africaines 22, no. 87–88 (1982): 363–85.

———. “Quatre siècles d’histoire d’une région du Moogo.” Journal des Africanistes 52, no. 2 (1988): 7–51.

Kirakoya, Mamadou. Mamadou Kirakoya, former indigo dyer, Rimassa (Burkina Faso). Interview by Laurence Douny, November 7, 2013.

Kirakoya, Moussa. Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso). Interview by Laurence Douny, April 27, 2014.

———. Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso). Interview by Laurence Douny, April 28, 2014.

Kirakoya, Noufou. Noufou Kirakoya, Zomkalga, (Burkina Faso). Interview by Laurence Douny, December 12, 2013.

———. Noufou Kirakoya, Zomkalga, (Burkina Faso). Interview by Laurence Douny, April 28, 2014.

Kirakoya, Yacouba. Yacouba Kirakoya, indigo dyer, Zomkalga, (Burkina Faso). Interview by Laurence Douny, April 26, 2014.

Marty, Paul. Études sur l’Islam en Côte d’Ivoire. Paris: E. Leroux, 1922.

Tauxier, Louis. Le Noir Du Soudan. Pays Mossi et Gourounsi. Documents et Analyses. Paris, 1912.

———. Le noir du Yatenga: Mossis, Nioniossés, Samos, Yarsés, Silmi-Mossis, Peuls. Paris: E. Larose, 1917.

Wenger, Etienne. Communities of Practice: Learning, Meaning, and Identity. Cambridge: Cambridge University Press, 2001.

[1] Kirakoya, Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso), April 28, 2014; Izard, “Quatre siècles d’histoire d’une région du Moogo,” 14.

[2] A period of prosperity and economic influence in the Yatenga under king Naaba Kango (1757-1787). Izard, “La politique extérieure d’un royaume africain : le Yatênga au XIXe siècle,” 363.

[3] Marty, Études sur l’Islam en Côte d’Ivoire, 405.

[4] Wenger, Communities of Practice.

[5] Gosselain and Smolderen, “Les fantômes du Dendi Lorsque surgissent les restes d’une ancienne filière textile au Nord Bénin”; Holas, “Teinturiers Mossi à Dimbokro”; Marty, Études sur l’Islam en Côte d’Ivoire.

[6] Tauxier, Le Noir Du Soudan. Pays Mossi et Gourounsi. Documents et Analyses., 215; Héritier and Izard, Les Mossi du Yatenga, 12.

[7] Kirakoya, Yacouba Kirakoya, indigo dyer, Zomkalga, (Burkina Faso).

[8] Tauxier, Le noir du Yatenga, 535.

[9] Kirakoya, Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso), April 27, 2014.

[10] Tauxier, Le noir du Yatenga, 216.

[11] Indigo balls made with the wild climbing liana called sankango (Lonchocarpus cyanescens) were found in the Yatenga but started to become rarer in the 19th century. Maranse imported indigo balls made of this plant from Bobo-Dioulasso and Ivory Coast.

[12] This variety is widespread in the Sahel. Gardi, Gardi, Bernhard. Woven Beauty: The Art of West African Textiles, 22.

[13] They did not sell fabrics or yarns to their customers. They bought plain white cloth to dye and sell themselves on local and regional markets as well as in Mali and Ghana.

[14] Kirakoya, Noufou Kirakoya, Zomkalga, (Burkina Faso), December 12, 2013.

[15] The Mossi and the Foulsé, who were exclusively farmers and who established long-term friendship and trust with the Maranse dyers of Marangho, realized that the dyeing activity was very profitable.

[16] Wenger, Communities of Practice.

[17] Kirakoya, Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso), April 28, 2014.

[18] The secret and magical nature of the artifact meant it could not be described in the interviews. Kirakoya, Noufou Kirakoya, Zomkalga, (Burkina Faso), April 28, 2014.

[19] Kirakoya, Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso), April 27, 2014.

[20] Afrique occidentale française. Gouvernement général de l’Afrique occidentale française., Territoires du Haut-Sénégal Moyen-Niger. 1900-1903, 82.

[21] While some dyers such as the Samogo developed a special dye made of half natural and half synthetic materials that would allow them to carry on dyeing in pits, the Maranse of the Marangho site abandoned experiments with synthetic dye materials because of the high cost of these experiments and of the materials themselves, especially at a time (early 1970’s) when they were experiencing very low sales.

[22] Kirakoya, Mamadou Kirakoya, former indigo dyer, Rimassa (Burkina Faso).

[23] The shortages began in the late 1960s, in the context of a series of historical droughts. They were particularly drastic and followed by famines in 1968-1973 and 1983-1984, although droughts have been common in the Sahel across the centuries. The shortages forced dyers to search for water across the area.

[24] In the early 20th century, the village council ordered a prohibition on the cutting of useful trees such as the shea or néré (Parkia biglobosa) and the kogolouweogo or the ‘guardian of the bush’ as these trees were traditionally used as medicines. Butter and condiments were also produced by women to be consumed daily and sold by them on local markets.

[25] Kirakoya, Moussa Kirakoya, indigo dyer, Zomkalga (Burkina Faso), April 27, 2014.